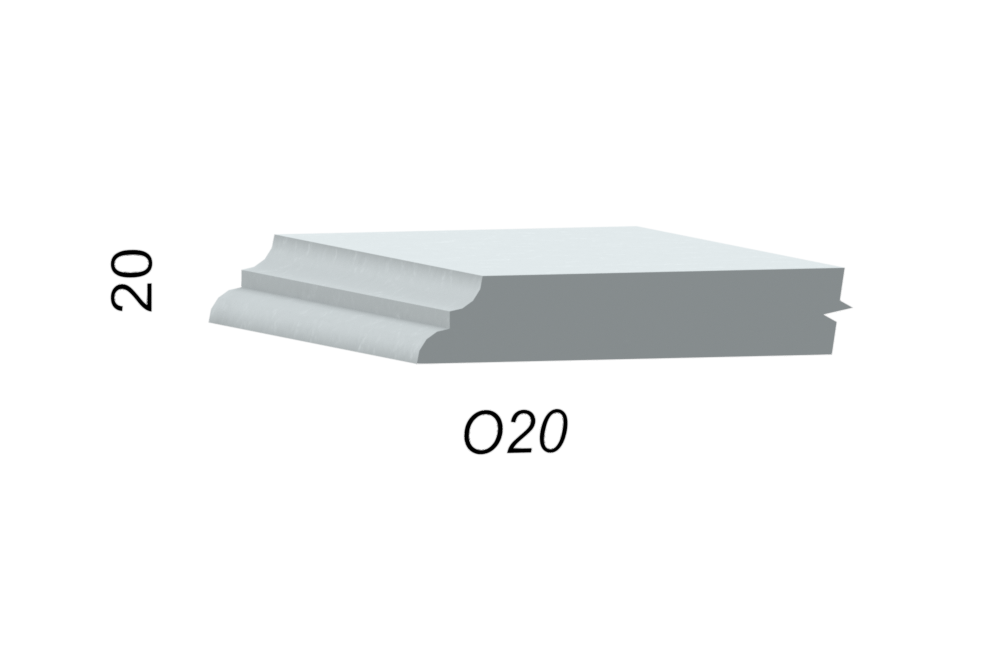

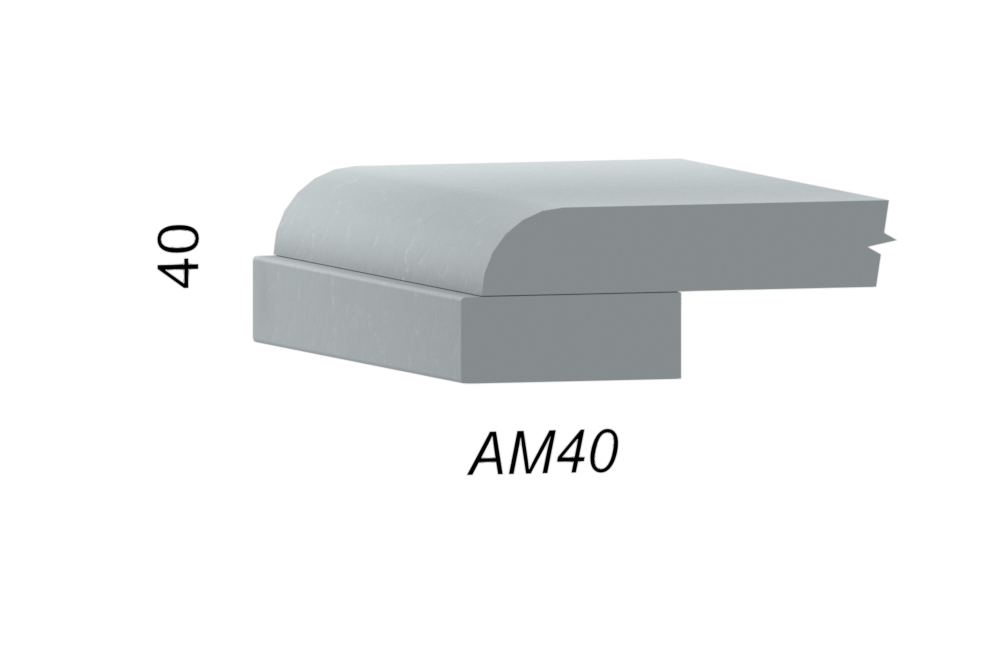

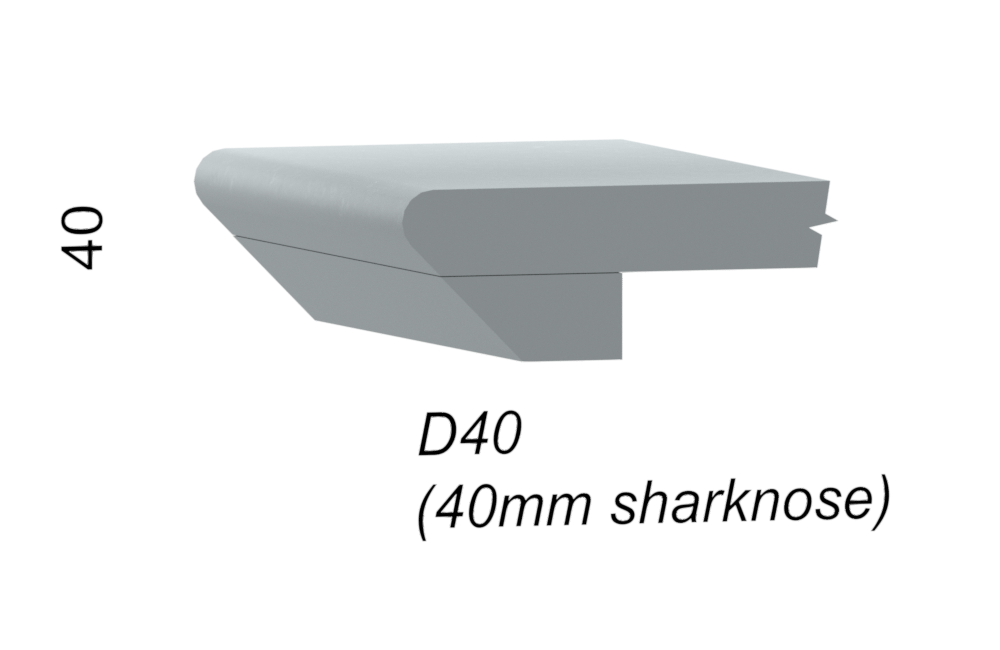

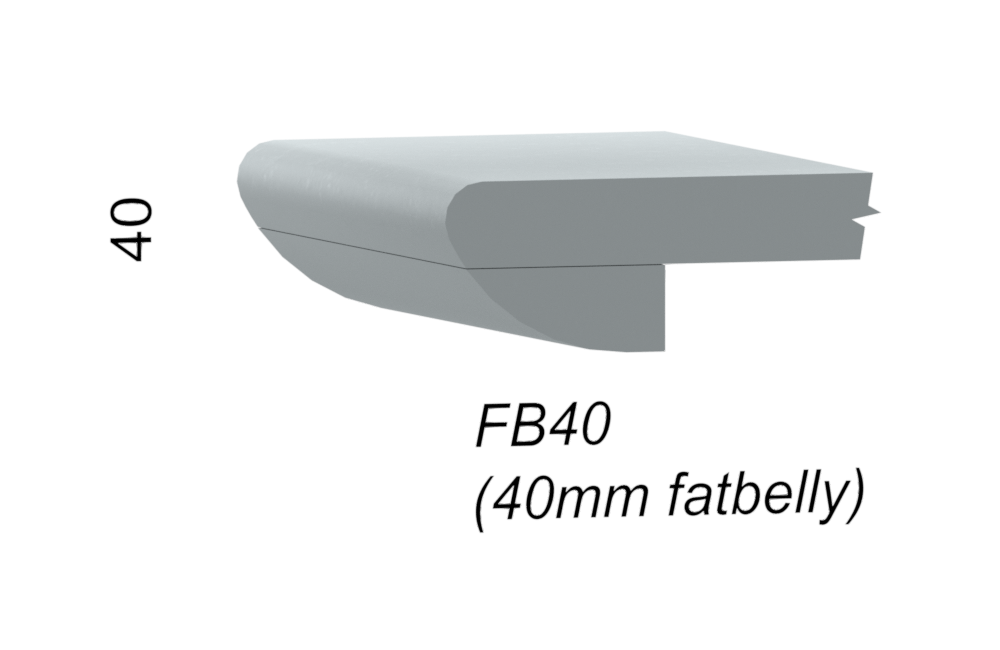

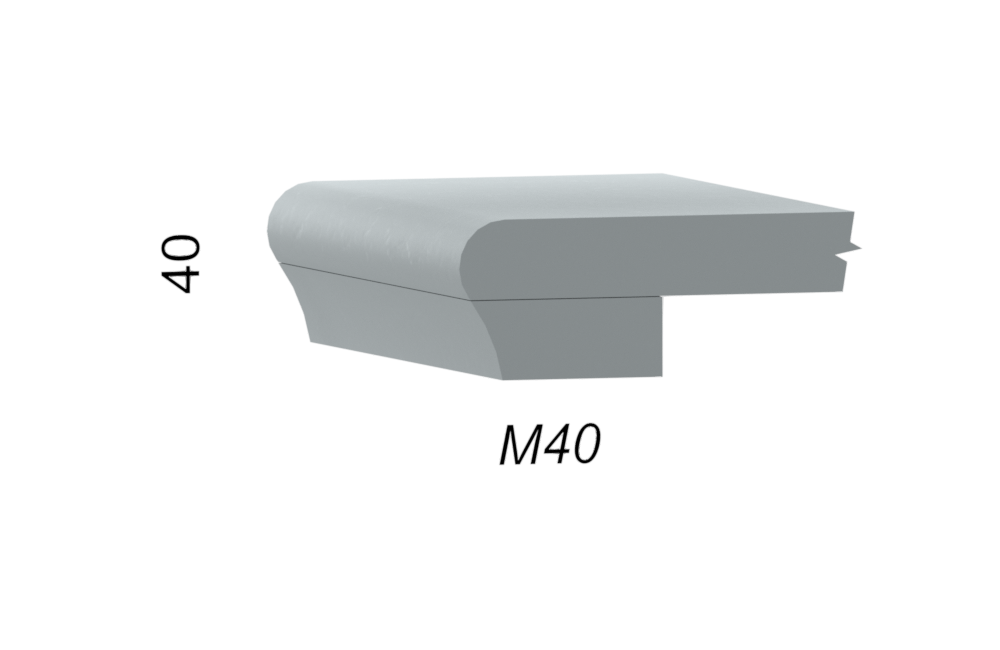

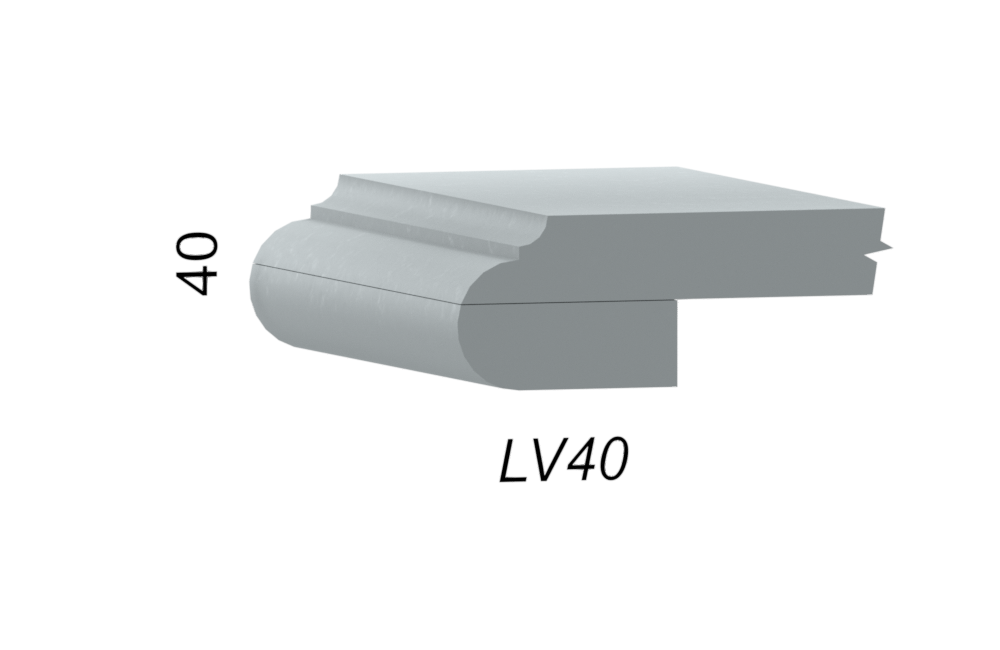

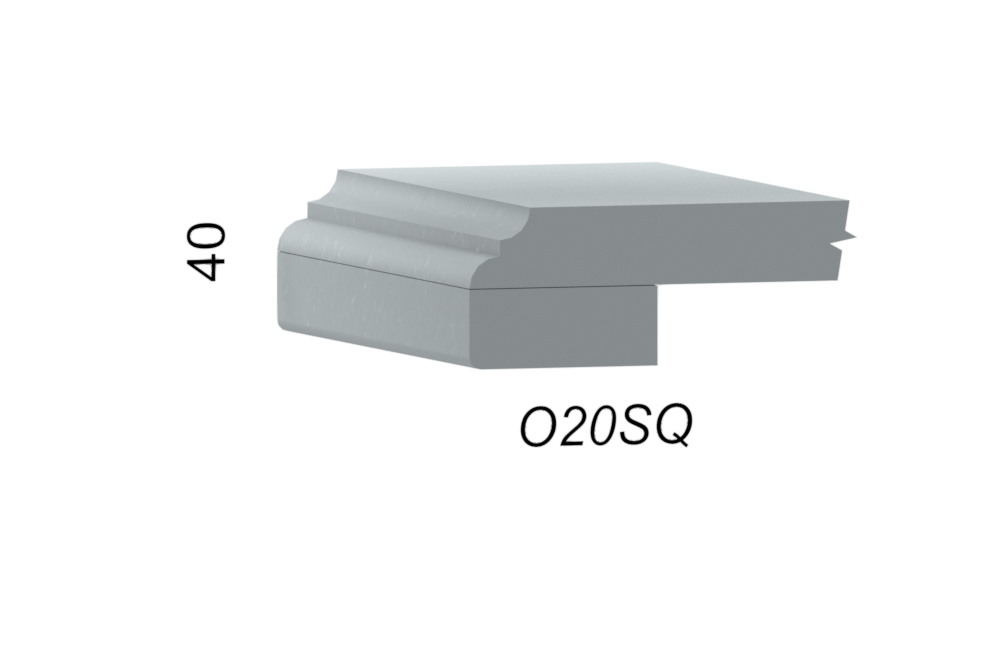

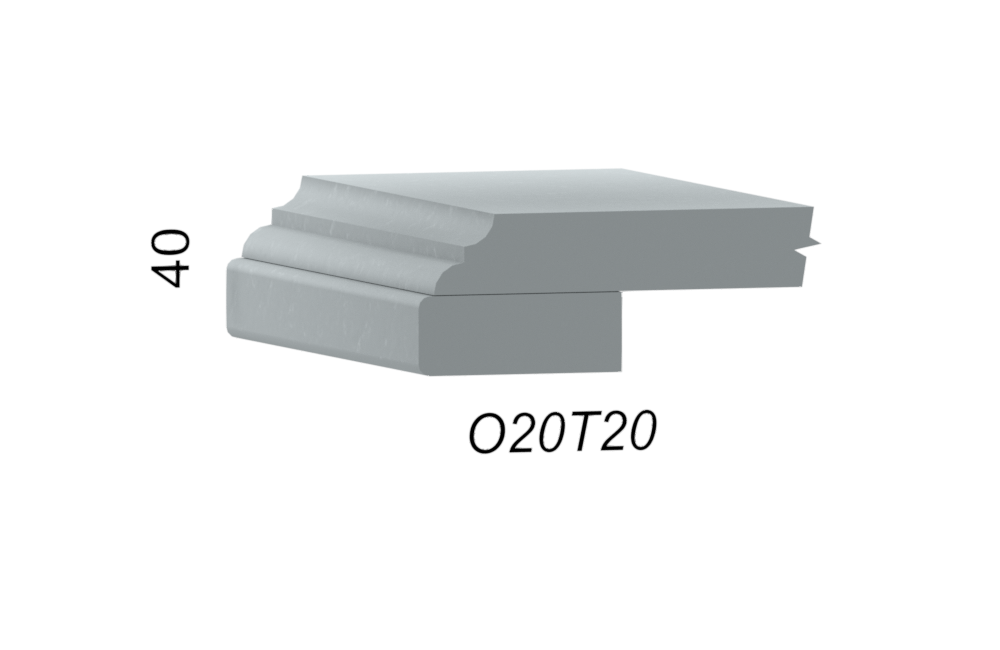

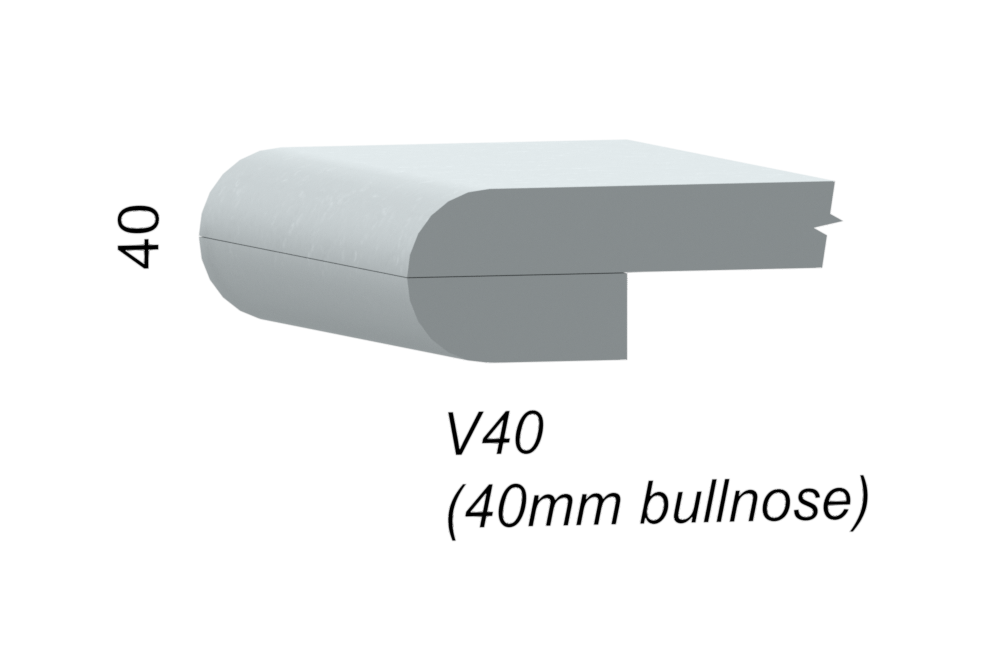

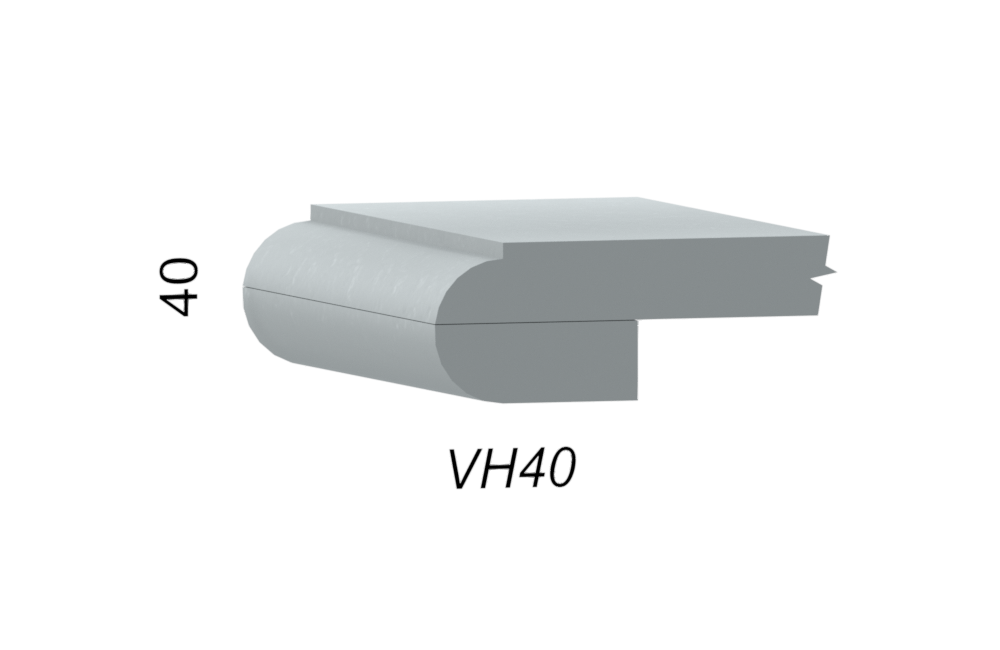

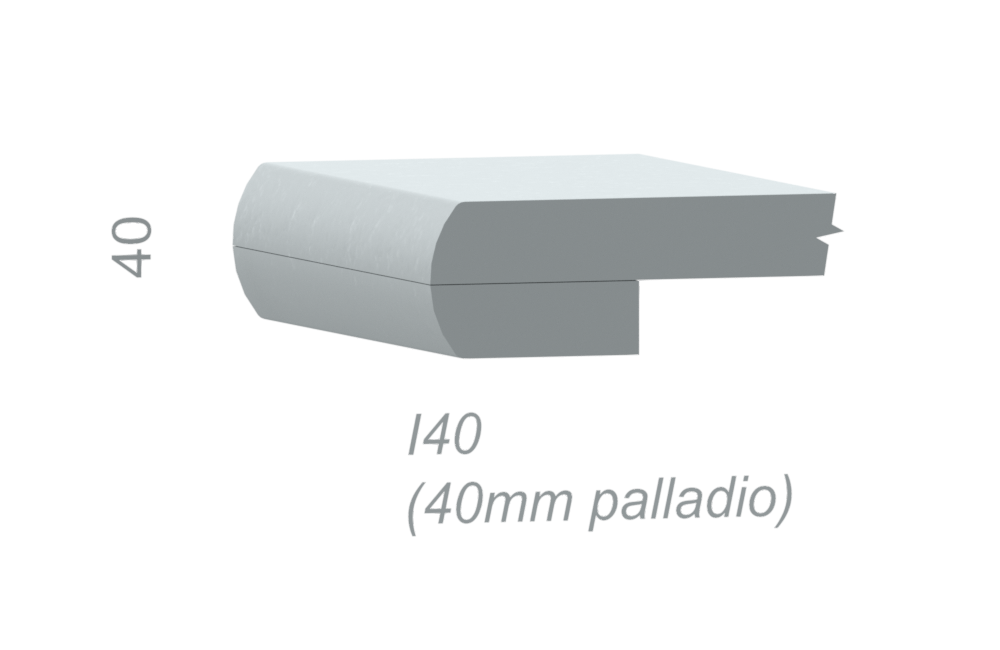

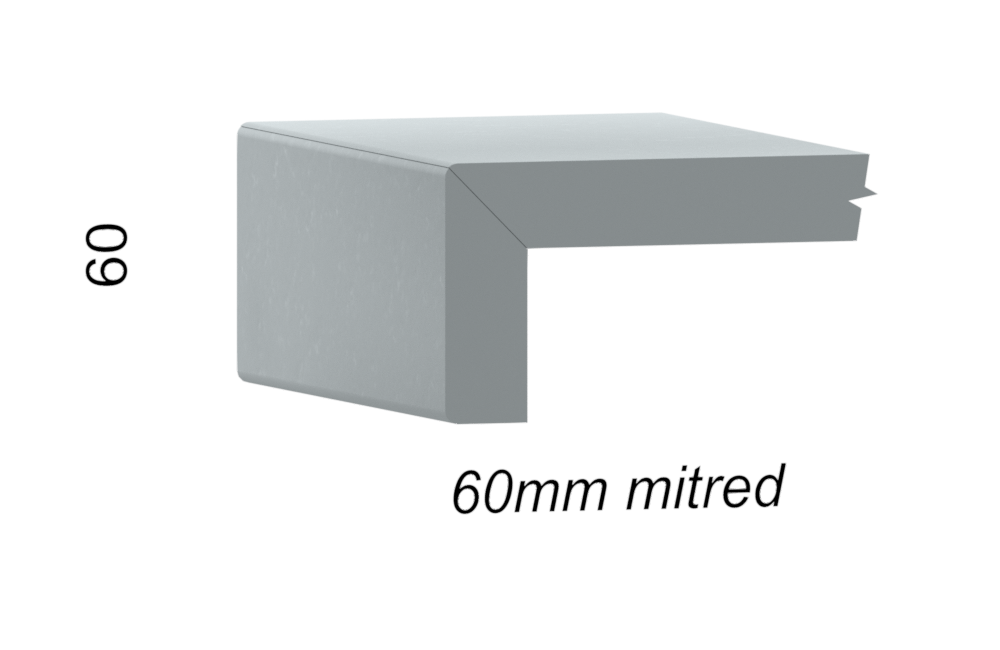

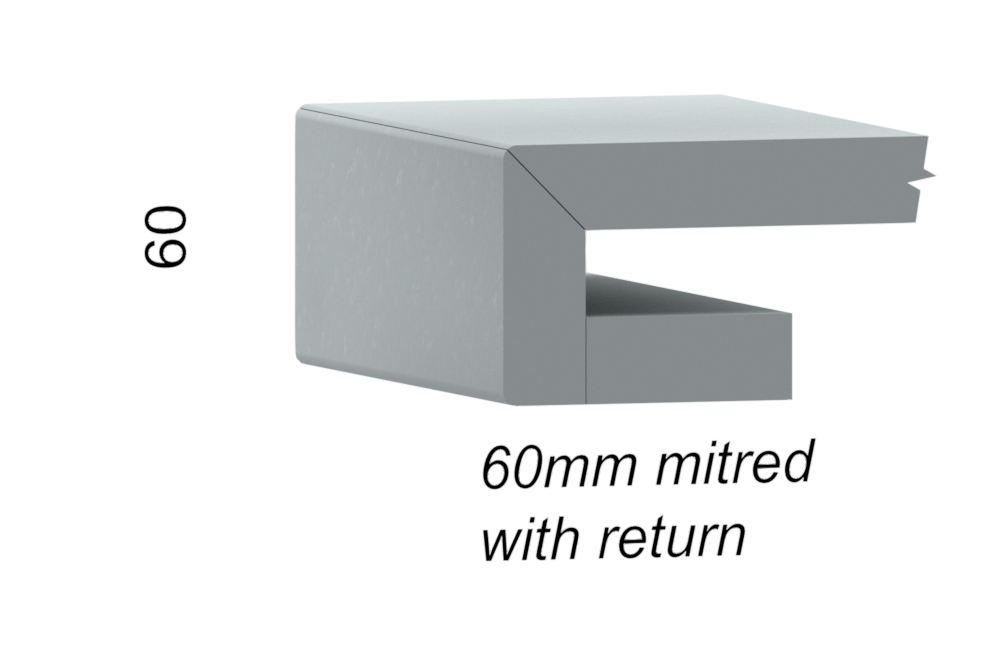

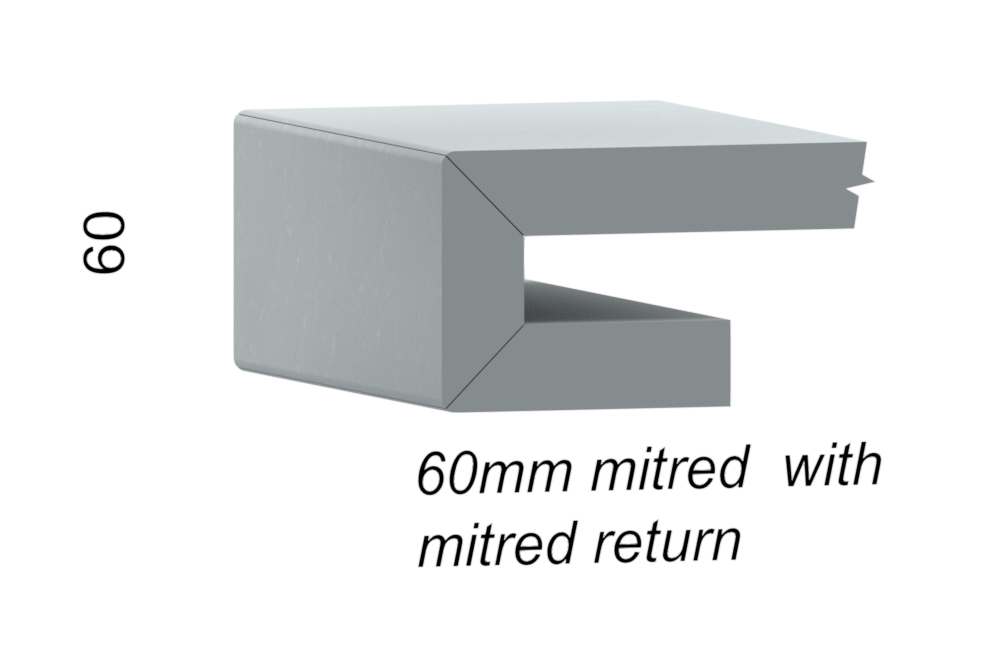

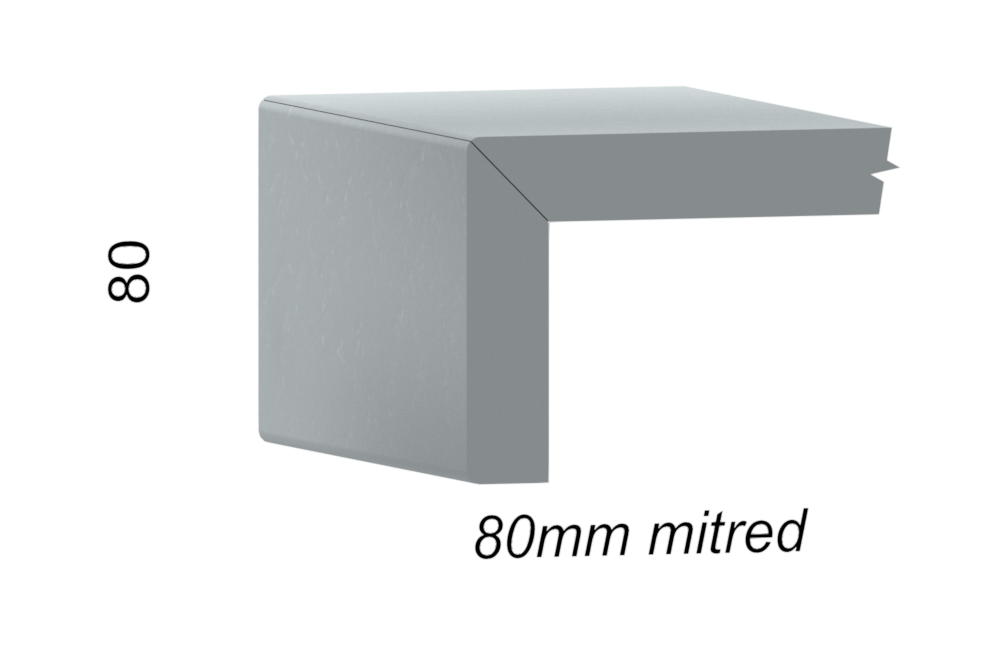

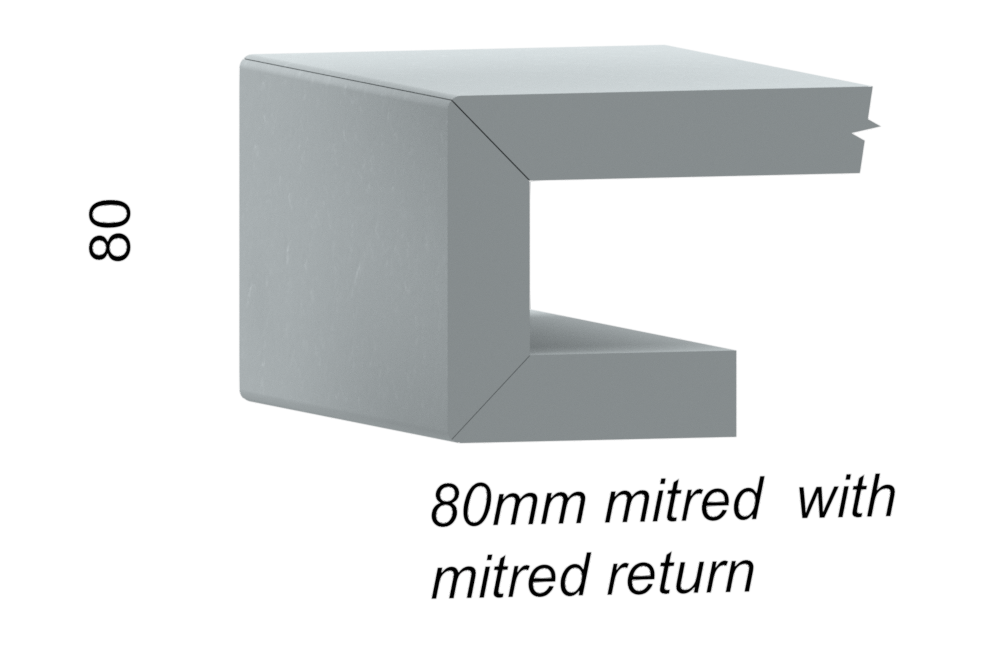

Common stone benchtop edge profiles

Modern CNC control technology makes stone benchtop profiles possible, which would otherwise not be achievable to the required precision. It also makes the edge details more affordable than the time taken to do them all by hand. Although we at Global Marble & Granite will always touch up edges by hand after the CNC machine stage to ensure a perfect finish.

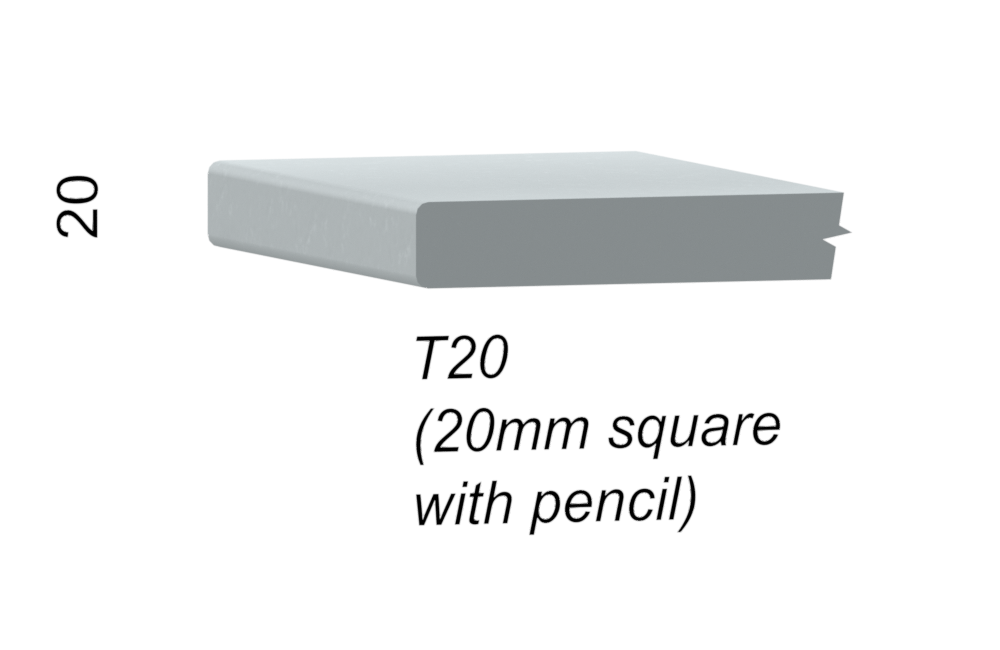

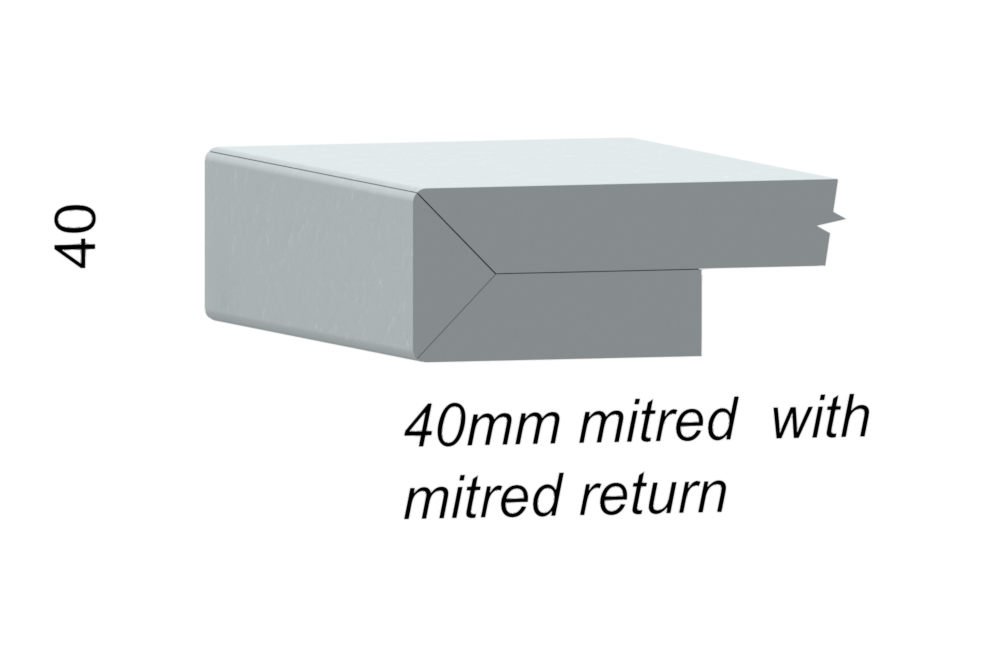

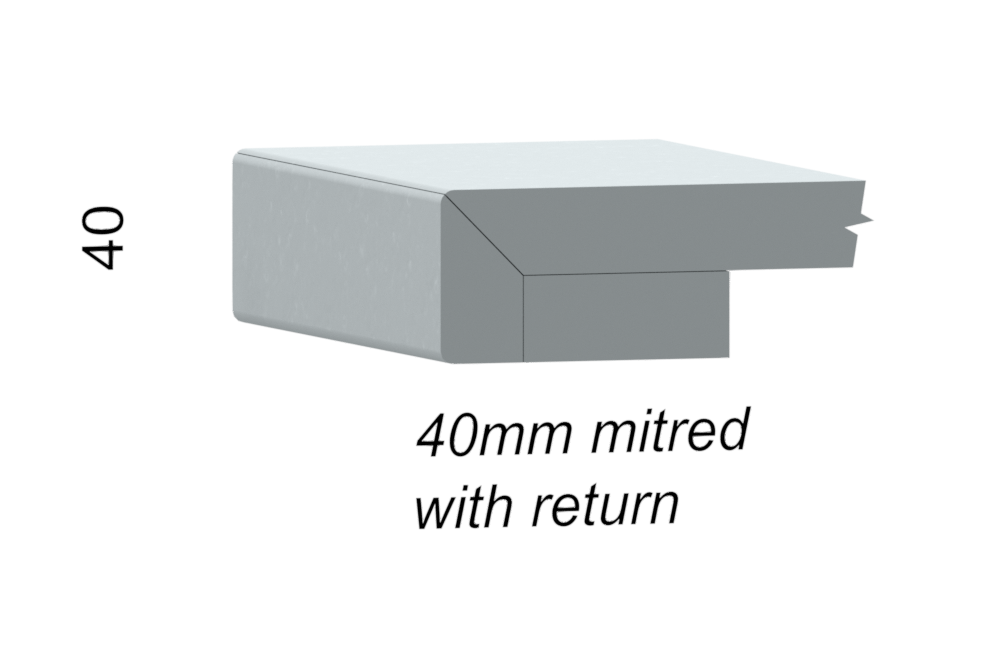

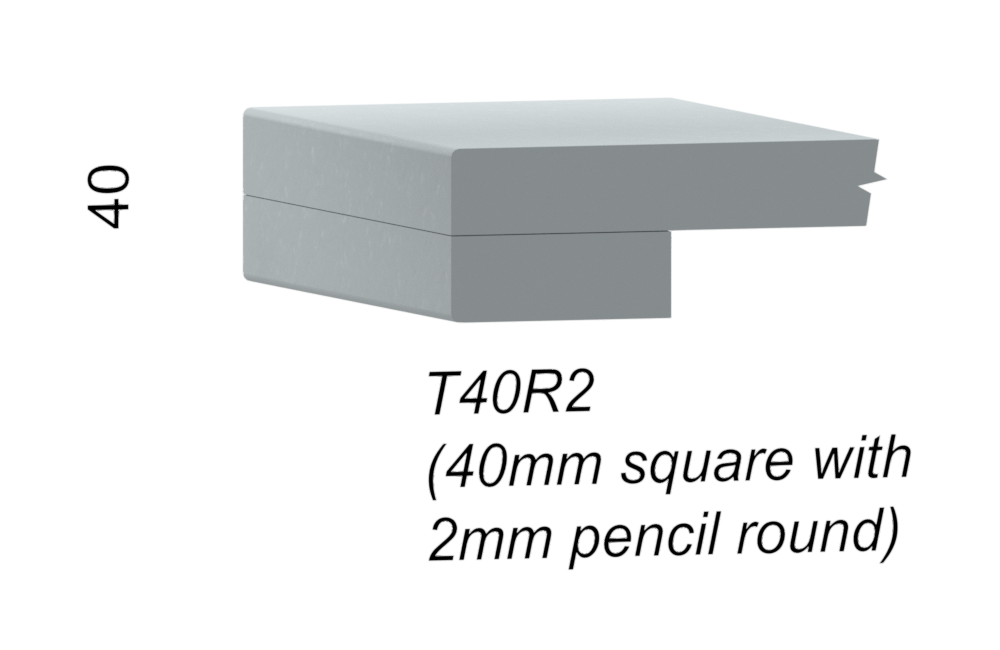

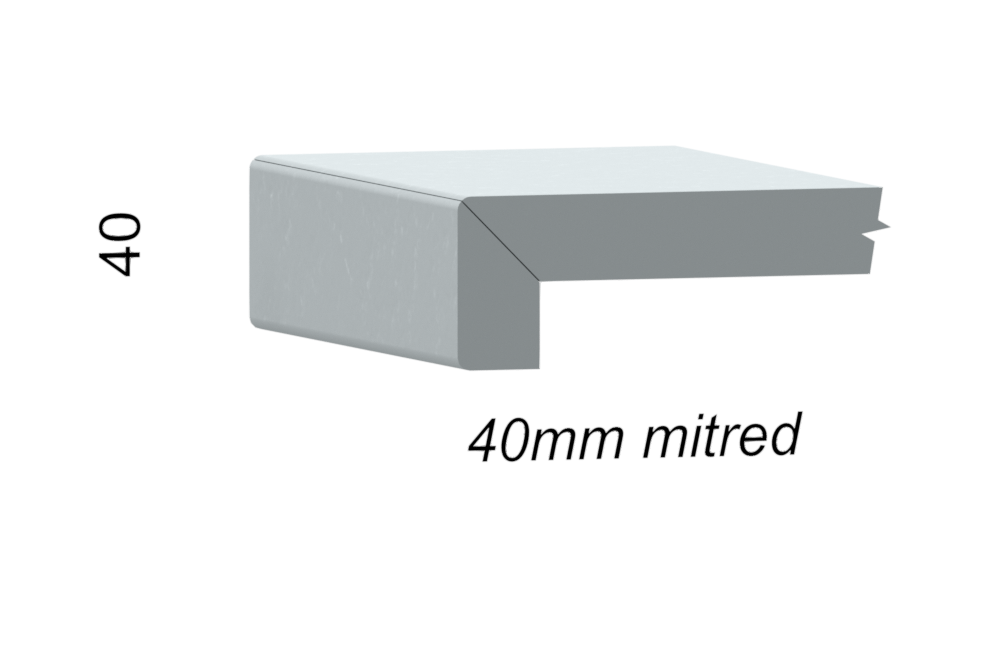

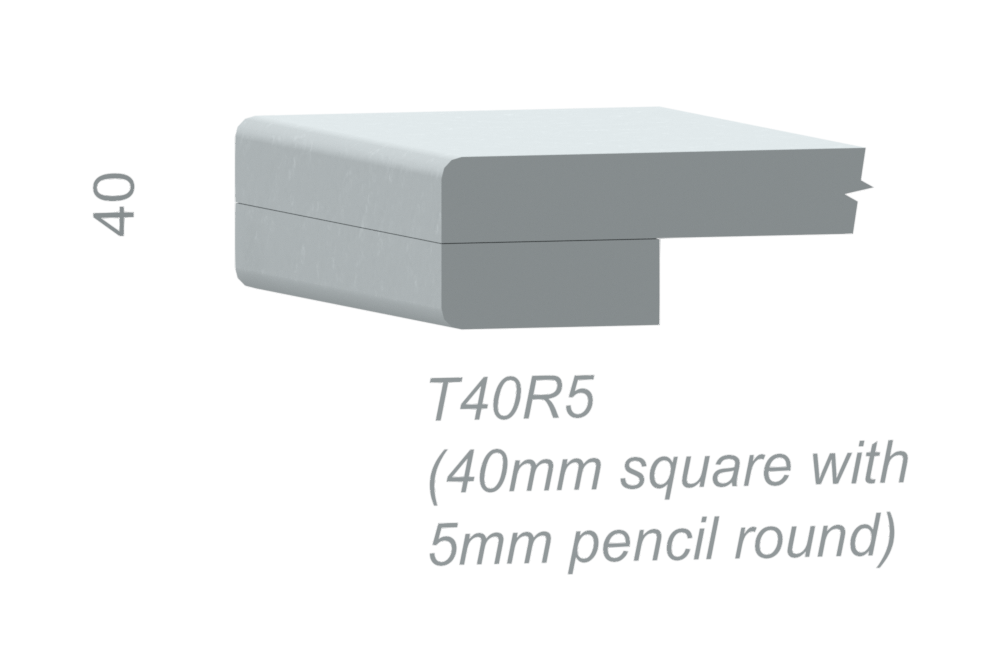

In recent years simple square edges with pencil round are in fashion like the T20 and the T40 or all the mitred versions. All our square edge profiles will have a pencil round finish as this is a little less prone to chip than an arris, bevel or chamfer. We recommend a minimum of R2 radius to all edges on engineered stone to avoid chipping and a minimum of R5 on all natural stones e.g marble or granite. All external corners will be rounded to best match the edge detail or as requested.

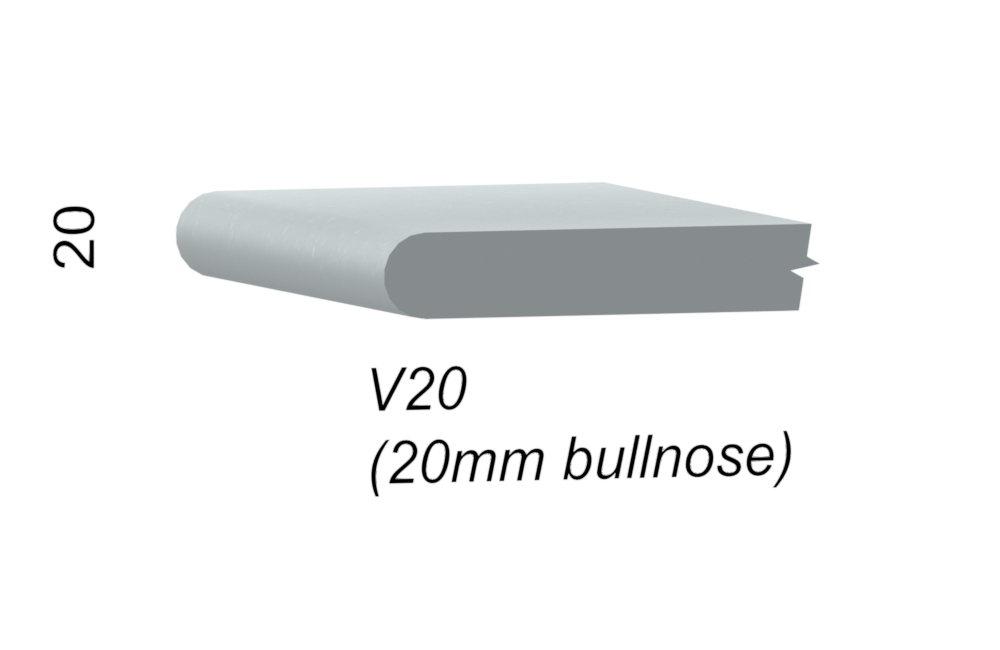

Below you see a selection of the most commonly used edge profiles for stone benchtops.